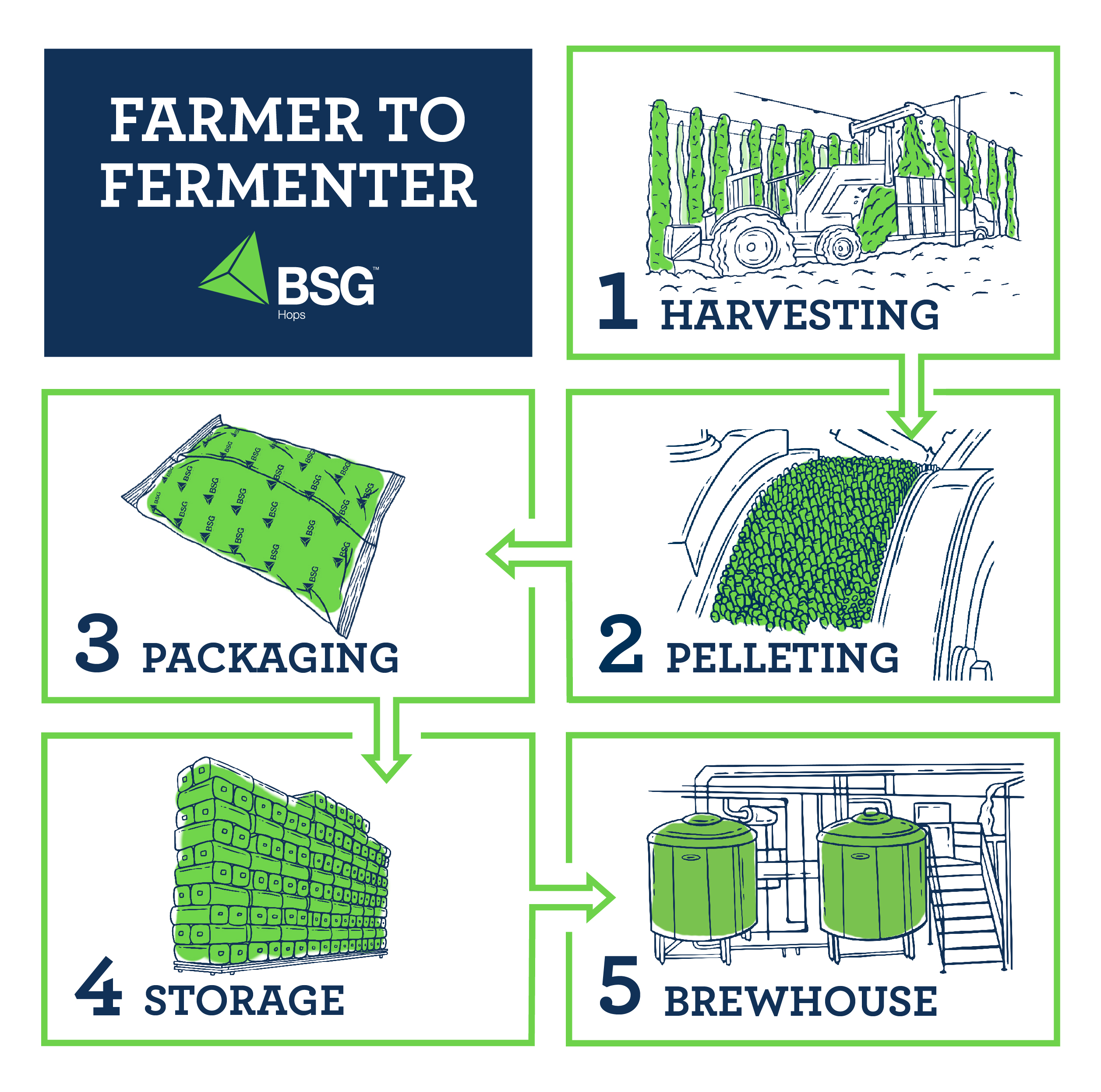

Join us in learning how BSG Hops processes and packages hops for peak freshness.

BSG Hops is based in the Yakima Valley of Washington, the heart of the US hop growing region. We are dedicated to supplying the brewing industry with the highest-quality hops through careful control of the entire supply chain. Our headquarters was built in 2014 and has expanded almost every year since. In 2020 our hop processing facility received FSSC 22000 certification. From harvest and processing to storage and shipment, BSG Hops maintains full traceability and regulatory compliance.

Harvesting

The heart of the BSG Hops processing facility is a completely sealed and clean system: once the bales go into the bale-breaker, the system is completely closed all the way through to the inert atmosphere packaging. The production room is secure, floors are sealed and polished for a clean environment, and interior walls are lined with metal panels. The entire state of the art processing facility was designed to create a total ‘Food Grade’ environment.

Pelleting

Our unique pelleting system is developed to maintain a constant feed to the pellet mill with no interruptions, allowing the pellet temperature and density to be controlled with minimal fluctuation. This enables the mill’s internal components to be adjusted on the fly, allowing fine-tuning of the pellet density without shutting down. Constant real-time temperature monitoring and automatic cooling ensures preservation of volatile aroma compounds that would otherwise be lost.

Packaging

Atmospheric controls with real-time monitoring of the oxygen present within the packaging machine automatically adjust the nitrogen volume and ensure that every package contains minimal residual oxygen.

Storage

Our Yakima campus has 84,000 square feet of refrigerated storage and can hold roughly 7 million pounds (the exact capacity depends on the ratio of whole hops bales to pellets), with an additional 15,000 square feet added in 2018. All hop storage areas are maintained at 31°F.

Brewhouse

Our network of distribution centers across North America have dedicated cold storage for hops, keeping our grower's hops in peak condition and allowing us to supply you from a warehouse in your region, ensuring your brewery gets the greatest quality hops for your brew.